Energy Storage: Hope in Hot Temperatures

Heating furnaces with renewable energy would be a quantum leap for steel and glass industries. It is one of the goals of Dr. Klarissa Niedermeier. She develops a heat storage system for temperatures above 700 °C and uses liquid metal for this purpose. The researcher and her team will present the only prototype of this kind at this year’s Hannover Messe.

If there was a supreme discipline in the development of heat storage systems, it would be high-temperature heat storage systems. These systems designed for use in industry store energy in the form of heat and reach temperatures of more than 500 °C. Liquid salts or solids are the media of choice for storing energy. But similar to sports competitions, there is an ultimate goal in the development of heat storage systems, something like the “ironman” of all projects: Storage of heat above 700 °C, which is as hot as lava.

To date, gases heated with electrical power have been used in this temperature range. They transfer their heat to a storage material that absorbs it. This storage material may be steel, volcanic rock, or slag. Dr. Klarissa Niedermeier from KIT’s Institute for Thermal Energy Technology and Safety, however, is pursuing an entirely new approach.

Issue 2024/1 of the research magazine lookKIT is dedicated to the efficient use of resources and the circular economy.

Read NowHeat Transfer a Hundred Times Better

Together with her team, the process engineer has developed a heat storage system based on lead-bismuth. She is among the first researchers worldwide using liquid metals in heat storage systems. “Thermal conductivity of liquid metals is 100 times higher than that of other materials,” Niedermeier says. “That is why liquid metals are very well suited for transporting and transferring heat.”

The researcher has been working on the technology for six years now. The 35-year-old engineer wants to help branches with a high resource consumption to better use the weather-dependent renewable energy sources. Industry processes in Germany consume 400 terawatt hours of heat per year, corresponding to 20 percent of the country’s total energy consumption. Steel, glass, and concrete are processed, molten, and dried at temperatures of up to 3000 °C every day. And these temperatures must be kept on a stable level. “90 percent of the fuels used for these processes are of fossil nature,” the engineer explains. “This must be changed.”

First approaches have been tested already, such as the electrification of processes or the use of hydrogen as energy carrier. With her liquid metal-based heat storage system, Niedermeier wants to mitigate fluctuations of power supply from renewable sources and to enable simple, inexpensive, and rapid energy storage at temperatures that are as close as possible to those of industrial processes.

Ceramic Beads as Storage Material

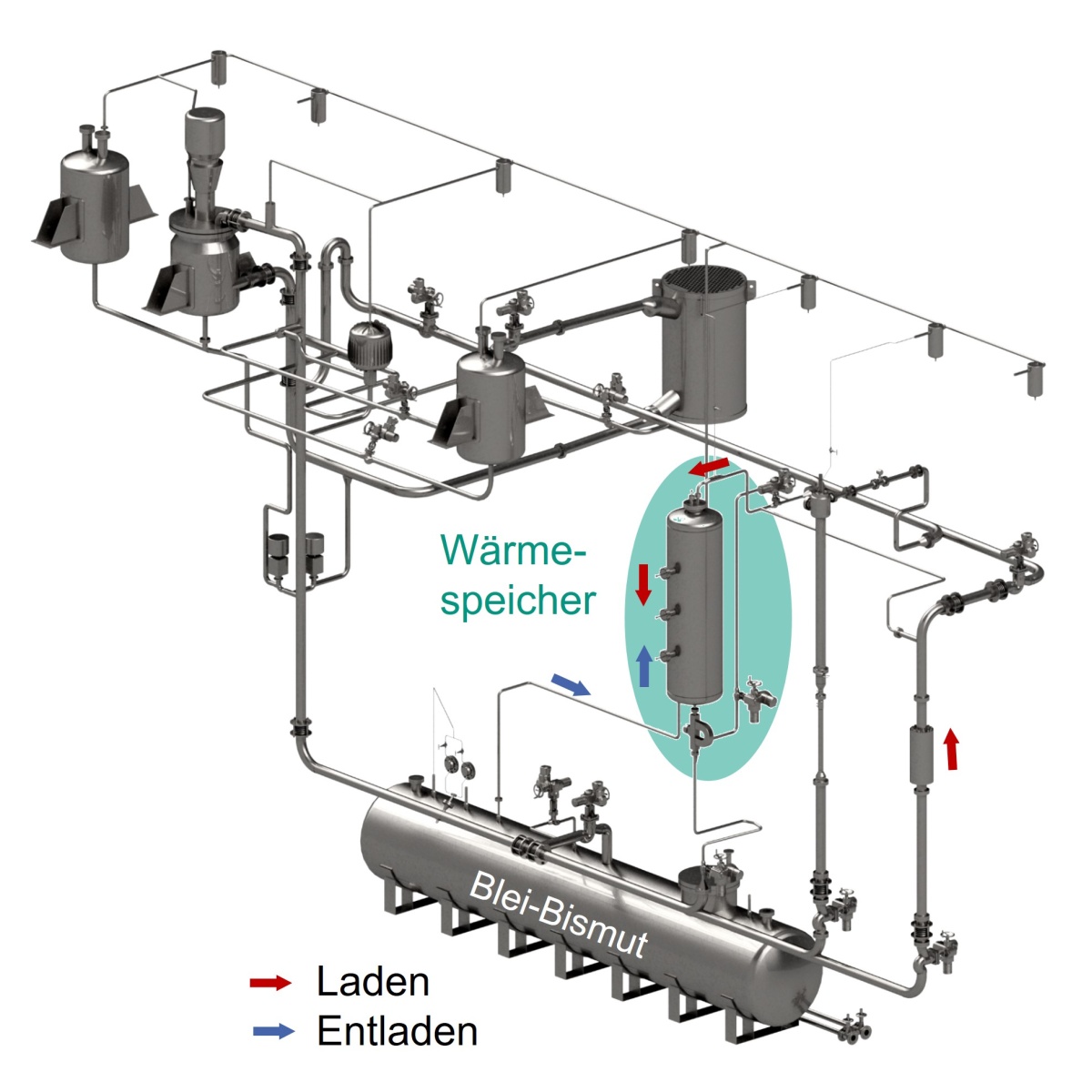

The new type of systems works as follows: Circulating liquid lead-bismuth is heated to more than 700 °C using electrical power. Then, the liquid metal passes through small, white ceramic beads in a steel tank and releases its heat to them. When the heat is needed again, the cooled liquid metal is returned through the beads and, thus, heated to more than 700 °C. The simulations run by Klarissa Niedermeier and her team at KIT’s liquid-metal laboratory KALLA (KArlsruhe Liquid Metal LAboratory) confirm that lead-bismuth allows for a more rapid heating of the heat storage system. Moreover, its packing can be denser than in case of gas. Smaller tubes, less space, less costs, and less time are needed.

Why did nobody think of using liquid metal in heat storage systems before? The first reason is a logistic one, Niedermeier points out. There are only few closed loop systems in the world, in which such a heat storage system can be tested. KALLA has a big lead-bismuth cycle that was built to study the cooling of fuel rods in times of nuclear research. Meanwhile, it is used for new projects in the area of renewable energy sources. “The cycle has been in operation for more than 20 years now. During this time, the team has gained vast know-how,” Niedermeier explains. “Moreover, liquid metals are highly corrosive, especially at high temperatures. KIT is developing special steel alloys for the pipelines and loops of the system.”

The other reason why only few researchers work with liquid metals in heat storage systems is of physical nature: In principle, these metals cannot store heat well. “First, you must have the idea to use liquid metal as a transport means only and not as a storage material in the tank,” the engineer explains.

Partnerships Wanted for 700 °Celsius and More

In spite of all advantages, Niedermeier points out: “There are still many open questions.” So far, the heat storage system has been tested at only up to 400 °C and the system has not yet been optimized. The team is looking for a cheaper storage material and is trying to further improve energy density. Moreover, pumps and valves must be tested for use with molten lead-bismuth at temperatures above 500 °C.

At Hannover Messe, Niedermeier’s team hopes to establish contacts to companies running energy-intensive high-temperature processes or producing waste heat at high temperatures and wishing to store it. At the world’s biggest trade show, the team will present a model of the heat storage system. Its size will be about half that of the real system at KIT that is designed for the storage of 100 kilowatt hours of heat. Niedermeier explains: “This is the first liquid-metal heat storage system of this kind worldwide having such a capacity. We want to show that the principle works and that its potential for the defossilization of industry is great.”

Isabelle Hartmann, March 25, 2024

Translated by Dipl.-Übers. Maike Schröder

KIT at Hannover Messe 2024

Mobile learning robots for agile production systems in the circular economy, the recycling of concrete and the targeted anonymization of large amounts of data are among KIT's key topics in the Future Hub (Hall 2, Stand B35). At Energy Solutions (Hall 13, Booth C76), the focus is on energy storage: Here, KIT will present a hybrid storage system for electricity and heat supply, heat storage using liquid metals, research on the safety of hydrogen storage, and energy storage materials for sodium-ion battery cells.

Press release on the Hannover Messe

Research magazine lookKIT "Ressources. Circular Economy. Energy"

Future Hub

AgiProbot: Smart Robots for Agile Production

Mobile learning robots with multiple sensors for an agile production system with uncertain product specifications. The project is aimed at enabling factories to autonomously adapt to constantly changing conditions. Remanufacturing is considered an ideal application: Used products are disassembled, refurbished, and reassembled, thus enhancing their quality to that of new products to enable reuse. Hence, remanufacturing contributes to a sustainable circular economy.

Recycling Check for Used Products

Diagnosis and inspection serve to find out whether a used product can be refurbished and reused again. This initial inspection of used products is usually made by humans. However, AgiProbot uses a diagnosis station to automate this process. For this, various optical measurement methods are applied, including a robot-controlled camera system, as well as artificial intelligence methods. In this way, the station learns to autonomously detect the current state and potential defects.

Analysis of Disassembly Processes

By means of a separate station, humans are watched while carrying out a manual disassembly. The sensors determine eye movements, human postures, and hand and arm movements in combination with tools and product components used. Moreover, single objects are captured on the working mat. These data are then input for robot programming by showing. The station will eventually disassemble the used product automatically.

Net-Zero Circular Concrete – Concrete without Emissions Harmful to the Climate

An innovative circular approach is pursued to produce concrete with a low consumption of resources and without emissions affecting the climate. Concrete waste resulting from the demolition of buildings is crushed and sorted into coarse and fine fractions. Limestone is added to the fine fraction to produce a binder at moderate process temperatures. The coarse fraction absorbs the carbon dioxide (CO2) produced in the course of the process. Together with the binder, it is used for producing new concrete. The pilot plant that is being set up at KIT will be used to gain the know-how for the production of larger quantities.

ANYMOS: Data Security in the Mobility Sector

Navigation systems and enabling purchases of tickets by mobile phone – these mobility services require data. How can these data be used to fulfil their purpose without permitting conclusions to be drawn about individual users? This challenge is the focus of the Competence Cluster on Anonymization for Networked Mobility Systems (ANYMOS) that will be presented jointly by KIT and FZI Research Center for Information Technology, an innovation partner of KIT. Researchers study the requirements and methods needed for the anonymization of data and assess circumstances under which anonymized data may be turned into personal data again. This will give rise to concrete applications, such as ticket systems that charge for the distance covered without revealing the passenger’s route.

Energy Solutions

Litona – Materials for Sustainable Sodium-ion Accumulators

KIT’s startup Litona develops energy storage materials for sodium-ion accumulators. Sodium-based accumulators can be produced with inexpensive and easily accessible resources. This will reduce future costs of batteries and the dependence of Europe on imports of resources. Litona’s work presently concentrates on Prussian white analogs. These storage materials are of interest for stationary energy storage and automotive applications in particular.

Heat Transfer with Liquid Metals

Thermal energy storage systems can store energy in the form of heat as needed by industrial high-temperature processes in chemical or metal processing industries. Liquid metals enable heat storage at very high temperatures. They are combined with ceramic beads having a high storage density and long-term storage capacity. A pilot plant will demonstrate operation of a liquid metal-based heat storage system.

Safe Hydrogen Storage Systems

Hydrogen (H2) is a clean, efficient, and reliable energy carrier for many applications. KIT has more than 30 years of experience in H2 safety research. Its hydrogen test center HYKA accommodates worldwide unique infrastructures for experiments covering various release and combustion scenarios. The PET (partially vented explosion tube) is used to study turbulent combustion processes in hydrogen-air mixtures found in partially vented geometries. These may be leaky H2 storage tanks in rooms with doors and windows. Researchers also develop 3D simulation programs to specifically analyze and improve safety conditions.

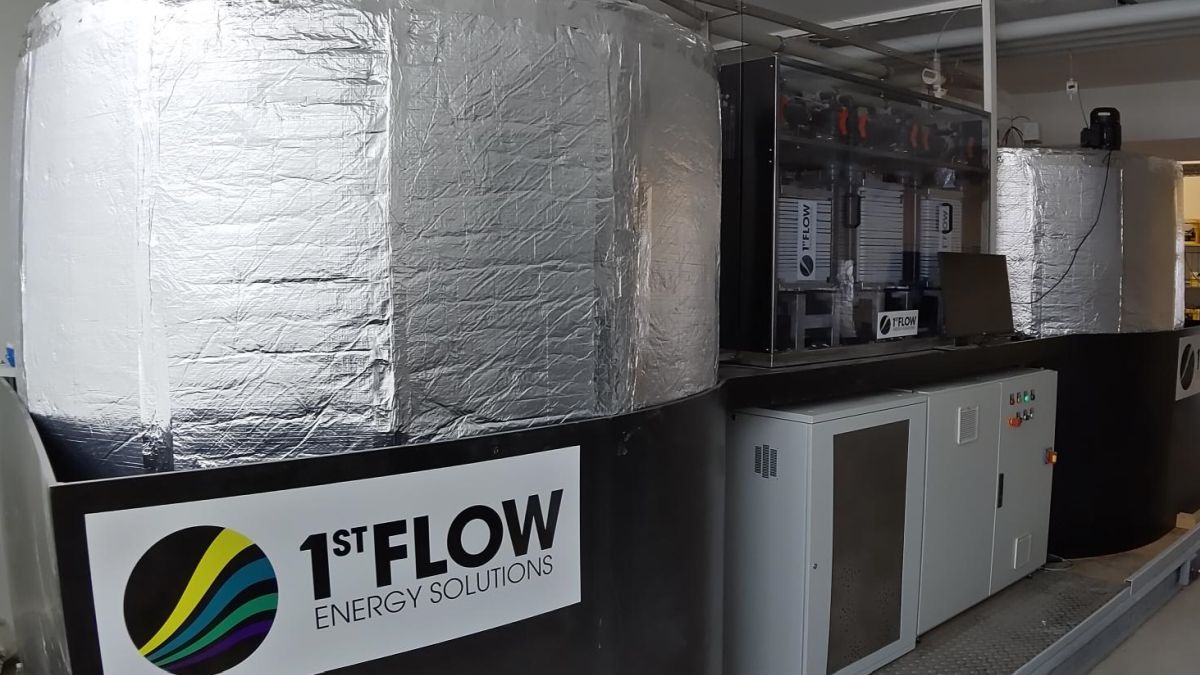

BiFlow – Hybrid Storage System for Power and Heat Supply

The energy transition and extended use of renewable energy sources require large storage capacities. The BiFlow project focuses on the development of a hybrid storage system that combines specific advantages of the lithium-ion battery with those of the redox-flow battery. The electrolyte tanks of the redox-flow battery are additionally used to store heat. In connection with a thermal coupling module, it increases the storage capacity and total efficiency of the system. This opens up new options for cost- and space-efficient co-storage.

Further Booths

KIT at Other Stands

At the stand of Baden-Württemberg international (hall 12, stand D15), the Innovation Campus “Future Mobility” (ICM) of Stuttgart University and KIT will provide insight into cutting-edge research for sustainable and digitalized production and mobility. ICM’s hydrogen world presents exhibits and projects of the fuel cell process chain. The RoboCable robot uses artificial intelligence to automatically lay cables and cable bundles. DeVee, a light electric vehicle demonstrator, presents subsystems of a future vehicle concept.

The Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST) will also be present at the stand of Baden-Württemberg international (hall 12, stand D15). KIT, Ulm University, and the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) cooperate in CELEST, the biggest platform for electrochemical storage systems in Germany.

At the stand of the Federal Ministry of Education and Research (hall 2, stand A28), the AppLHy! exhibit highlights the design and implementation of a combined transport route for liquid hydrogen and electric power. Power will be transmitted with the help of high-temperature superconductors.

The KIT Founders‘ Forge will be presenting itself together with nine spin-offs from KIT in the Startup Area in the Network Park (Hall 2, Stand D30). Two start-ups per trade fair day will be at the stand for talks and will also pitch on the Industrial Startup Stage. The KIT Founders' Forge is one of the largest university start-up centers in Germany and sees itself as an accelerator for innovative business ideas relating to the central future topics of our time.

Conference Program

KIT’s Contributions to the Conference Program

Tech Transfer Conference Stage (Hall 2, Stand B02)

Tuesday, April 23, 2024, 13.55 hrs

Panel Discussion: Welche Verantwortung trägt Forschung für eine nachhaltige Zukunft? (which responsibility does research have for a sustainable future?).

In German with live interpretation. Experts of information technology, mobility, and research transfer will discuss the role and responsibility of science in the context of climate change, resource scarcity, and impacts on society. The focus will be on the very rapidly developing use of artificial intelligence. The participants in the discussion will be: Ada Streb, FZI Research Center for Information Technology, Head of the Capital Office of FZI and Head of the Department of Innovation, Strategy, and Transfer; Dr. Alexander Viehl, FZI, Head of the Department of Intelligent Systems and Production Engineering; Dr. Sandra Kauffmann-Weiß, KIT, Managing Director of the Innovation Campus Future Mobility; and Dr. Walter Tromm, Spokesman of the KIT Energy Center. The discussion will be presented by Dr. Wolfgang Breh, Managing Director of the KIT Energy Center.

Tuesday, April 23 2024, 14.50 hrs

Presentation in English with live interpretation: Net-zero Circular Concrete

Dr. Peter Stemmermann, Institute for Technical Chemistry of KIT.

Wednesday, April 24, 2024, 10.25 hrs

Presentation in German with live interpretation: Collaborative Research Center 1574 – The Circular Factory for the Eternal Product

Manuel Zaremski, Institute for Human and Industrial Engineering of KIT

ENERGY 4.0 Academy (Hall 12, Stand D35/26)

Tuesday, April 23, 2024, 14.20 hrs

Presentation in German (without live interpretation): Neues thermisches Kopplungssystem für stationäre elektrische Energiespeicher im Gebäudesektor (new thermal coupling system for stationary electrical energy storage systems in the building sector)

Dr. Christian Kupper, Institute of Electrical Engineering of KIT

Thursday, April 25, 2024, 10.00 hrs

Presentation in German: Methane pyrolysis as a key element for emission-free hydrogen and carbon production

Prof. Dr.-Ing. Thomas Wetzel, Institute of Thermal Process Engineering of KIT

Chief Press Officer (acting), Channelmanagement Press