In spite of its relevance to biological research, the classical cell culture has its limits. In the tissue, cells live in three dimensions, whereas in the cultivation dish they can grow in two dimensions only. Scientists of Karlsruhe Institute of Technology (KIT) have now presented a process to produce three-dimensional and flexible substrates of any structure. This method opens up new possibilities for the investigation of cell movement and differentiation (Advanced Materials 22, 868 (2010)).

The earth is flat – at least for cells at the bottom of a Petri dish. Except for the uppermost cell layer on the skin or in the intestine, however, cells in the organism live in a three-dimensional and flexible environment. “All over their surface area they are in contact with neighboring cells and the extracellular matrix that gives the body tissue strength and elasticity,” explains Professor Martin Bastmeyer from the DFG Center for Functional Nanostructures (CFN) of KIT. The cells can adhere to its fibers consisting of various molecules or move as if they were in a three-dimensional jungle gym. The composition and structure of the matrix influence the behavior and the development of the cells which, in turn, synthesize, reconstruct, and deform the matrix.

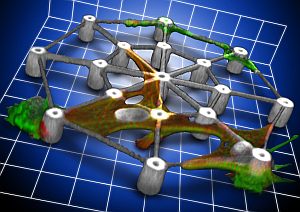

This interaction is studied by Bastmeyer using the newly produced artificial structures of elastic, long elements of less than a thousandth of a millimeter in diameter. For their production, the working group uses a process called direct laser writing. It was developed by the physicists Professor Martin Wegener and Dr. Georg von Freymann at CFN. A computer-controlled, focused laser beam writes in a photoresist like a pen in three dimensions. During development, the irradiated areas remain standing. They are then coated by a protein to which the cells can adhere.

Cardiac cells from chicken embryos sown onto these structures start to contract rhythmically and to bend the elastic, thin beams after a few days. “It is shown by comparative measurements with the atomic force microscope that they develop a tensile force of 47 Nanonewtons. This would be sufficient to move a mass of about 5 millionths of a gram,” explains the biologist Dr. Franziska Klein. “Roughly calculated, a cube of densely packed cells with an edge length of five centimeters could lift nearly five kilograms.”

Further experiments with other structures are aimed at finding out how cells react to various mechanical properties and spatial conditions of their three-dimensional environment. For these experiments, the team of biologists and physicists plans to produce larger and more complex structures, into which the cells can migrate as if into a porous sponge. The results may help to optimize tissue cultivation conditions and regenerative medicine with stem cells.

Literature:

Elastic Fully Three-dimensional Microstructure Scaffolds for Cell Force Measurements. Franziska Klein, Thomas Striebel, Joachim Fischer, Zhongxiang Jiang, Clemens M. Franz, Georg von Freymann, Martin Wegener, and Martin Bastmeyer. Advanced Materials 22, 868 (2010)

DOI: 10.1002/adma.200902515

Background Information:

Extracellular Matrix (ECM)

The ECM fills the space between the cells in the connective tissue in particular. It is a mixture of various components, the composition of which varies as a function of the tissue type. Among these components are various types of collagen that makes the tissue strong and elastic. The adhesion proteins fibronectin, laminin, or vitronectin are important for the attachment of cells. Cartilage is given its special properties by molecules such as hyaluronic acid or chondroitin sulfate. The ECM influences the cells via both its biochemical composition and its mechanical properties.

Direct Laser Writing (DLW)

Direct laser writing is a photolithographic process to produce three-dimensional microstructures of any type. In the microscope, photoresist moved in three dimensions by a computer-controlled, piezo-driven table is exposed through the objective to femtosecond pulses of a strongly focused laser beam. In the confined area in which the photoresist is hit by the beam, solubility of the material is changed. Depending on the type of photoresist, the irradiated or unirradiated sections are washed out in a developing bath. Due to the high optical resolution, DLW can produce structures of 150 nanometers (1 nanometer = 1 millionth of a millimeter) in objects with a maximum lateral extension of 0.3 mm and a height of 0.08 mm. The DLW system developed by the Center for Functional Nanostructures is presently being commercialized by the Nanoscribe GmbH spin-off. www.nanoscribe.de

Calculation of the Tensile Force of a Cube of Cells

This calculation is based on simplifying assumptions and therefore yields an approximative value only:

A cube with an edge length of five centimeters, which consists of densely packed (idealized) cubic cells with an edge length of 50 micrometers (0.05 mm), contains a billion cells (1000 x 1000 x 1000). A cell develops a force of 47 billionths of a Newton (47 Nanonewtons). The cell cube, hence, produces a force of 47 Newtons. Gravity with a force of 9.81 Newtons acts on a mass of 1 kg. Consequently, 47 Newtons are sufficient to lift a mass of 4.79 kg.

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.