Powerful, durable, and safe: these properties, combined with a low price, could soon secure batteries “Made in Germany” a place among the best in the world. This will be realized by including advanced approaches to quality assurance and analytics in production, which are now being developed and tested at the Karlsruhe Institute of Technology (KIT). The activities in the AQua battery research cluster are carried out in close cooperation with research partners in the “Battery research factory” initiated by the Federal Ministry of Education and Research (BMBF).

Ensuring maximum quality at minimum production costs – this is what scientists strive to achieve in a new research platform launched at KIT as part of the AQua (stands for: analytics/quality assurance) battery competence cluster. To do this, they first look at each production step, from the raw materials to the finished cell, in order to identify possible sources of errors. Subsequent measures include the optimization and automation of error handling during ongoing production so that a consistently high quality can be guaranteed in the end. “In production, every step has to be flawless. All steps are designed to work together, and any error can affect the later performance of the cells,” says Professor Helmut Ehrenberg from the Institute for Applied Materials (IAM-ESS) of KIT, who coordinates the research. “The performance of analytics and quality assurance therefore has a decisive influence on the quality, safety, and costs of a cell.” The researchers develop their solutions using methods of integrated production control and implement them in the entire process chain.

Research on Automatic Error Detection

In order to identify critical errors in the production process as early as possible and to interpret them correctly, the scientists in the AQua projects work, among others, according to the principle of Failure Mode and Effects Analysis (FMEA). “In doing so, we introduce errors in a targeted and controlled manner in order to precisely quantify the relationship between a disruption and its effects on the cells,” explains Dr. Lea de Biasi, one of the researchers in the project. “If we now define specific performance criteria as quality targets, we can set tolerance limits for all relevant process steps.” These are then applied directly in the production process. To this end, the AQua researchers also develop methods for recording critical influencing variables in real time. These include the homogeneity of the electrode coating or the residual moisture of the components at the start of cell construction. With automatic error detection, intermediate products are inspected by the machine immediately after the respective process step and defective pieces are rejected. “This also allows us to draw conclusions about the causes of errors and we can eliminate process disruptions at an early stage and avoid further costs due to rejects,” says de Biasi.

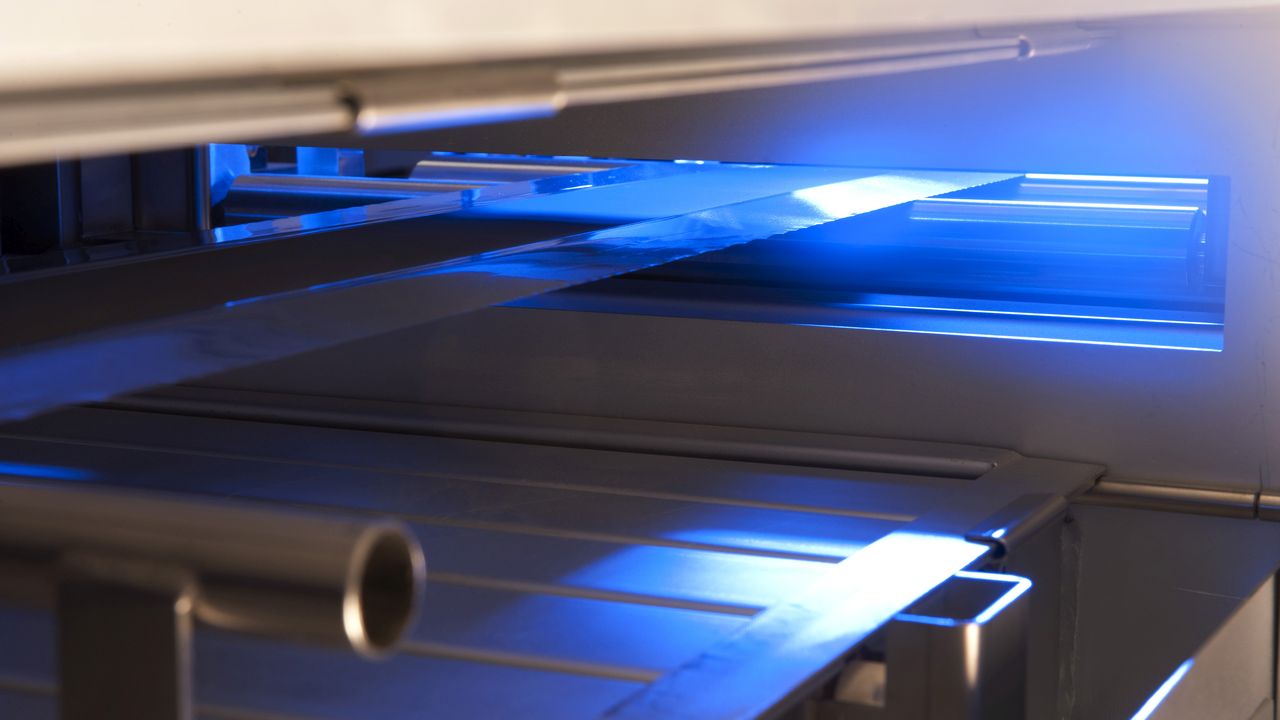

Semi-automated production lines ensure

flexible manufacturing. (Photo: Markus Breig, KIT)

Data Infrastructure for Fast Research Transfer

The new research platform is complemented by an accompanying project that is being coordinated at KIT by Dr. Michael Selzer from the Institute for Applied Materials – Computational Materials Science (IAM-CMS). It involves, among other things, exchanging the platform with the other battery competence clusters of the “Battery Research Factory” as well as cooperation projects with industry. However, the focus is on setting up a data infrastructure: “During the experiments and large-scale simulations in the AQua project, we obtain large amounts of data that have to be evaluated by specific data analysis methods using standardized workflows,” says Selzer. “With the data infrastructure, we provide sustainable access to this research data and the analysis tools.” This is a decisive contribution to quality assurance and to the transfer of research in the field of battery production, emphasizes Professor Britta Nestler from IAM-CMS who, as an expert in micro-structure simulation, plays a key role in the project. “In AQua, we want to develop a comprehensive and cross-process understanding of how the interaction of materials, production steps, and specific electrochemical features affect the structures and properties of the battery.”(mhe)

More information: https://www.bmbf.de/de/batterieforschung-in-deutschland-662.html

More about the KIT Energy Center: https://www.energie.kit.edu

In close partnership with society, KIT develops solutions for urgent challenges – from climate change, energy transition and sustainable use of natural resources to artificial intelligence, sovereignty and an aging population. As The University in the Helmholtz Association, KIT unites scientific excellence from insight to application-driven research under one roof – and is thus in a unique position to drive this transformation. As a University of Excellence, KIT offers its more than 10,000 employees and 22,800 students outstanding opportunities to shape a sustainable and resilient future. KIT – Science for Impact.