KIT and Intel Develop Microchip for Research-oriented Teaching

Students and researchers at the Karlsruhe Institute of Technology (KIT), together with the US chip manufacturer Intel, have developed a microchip designed for research and teaching - starting from the design process to tape-out and eventually raw die characterization. The chip is called KIT “Callisto” with a total area of four square millimeters and exploits Intel 16 which is Intel’s CMOS Finfet-16nm transistor technology. “It is the first non-planar field-effect transistor technology (FinFET) experience for our students. Most textbooks still center around planar CMOS technologies and we wanted to start with something much more modern”, says Professor Aghassi-Hagmann from the Institute of Nanotechnology at KIT, whose research group led the activities in the development of the chip. The project was enabled by the "Intel University Shuttle Program" (USP), in which the chip manufacturer cooperates with universities worldwide after a competitive selection phase.

Impressive commitment of the students

"Our microchip contains a number of test structures and circuits developed in several research projects, including for example circuits for controlling time-critical processes, diodes for particle detectors, integrated noise suppression and much more”, says Professor Jasmin Aghassi-Hagmann. Her colleague Professor Ivan Peric from the Institute for Process Data Processing and Electronics at KIT, whose research group was also involved in the chip development, adds: "Finfet transistors are optimized for space and energy efficiency. I am glad that our students got the opportunity to design circuits based on these novel devices." Peter Baumgartner, head RF engineer at Intel, guided the students throughout the project and helped them conclude the successful tapeout on time.

Bryan Casper, the coordinator of USP at Intel, was particularly impressed by the commitment of the KIT students in the joint project: "For us, it was confirmation that we can and should start training future specialists early during their studies.” The findings from the project are now being incorporated directly into the current curriculum of the Master's degree program in Electrical Engineering and Information Technology at KIT.

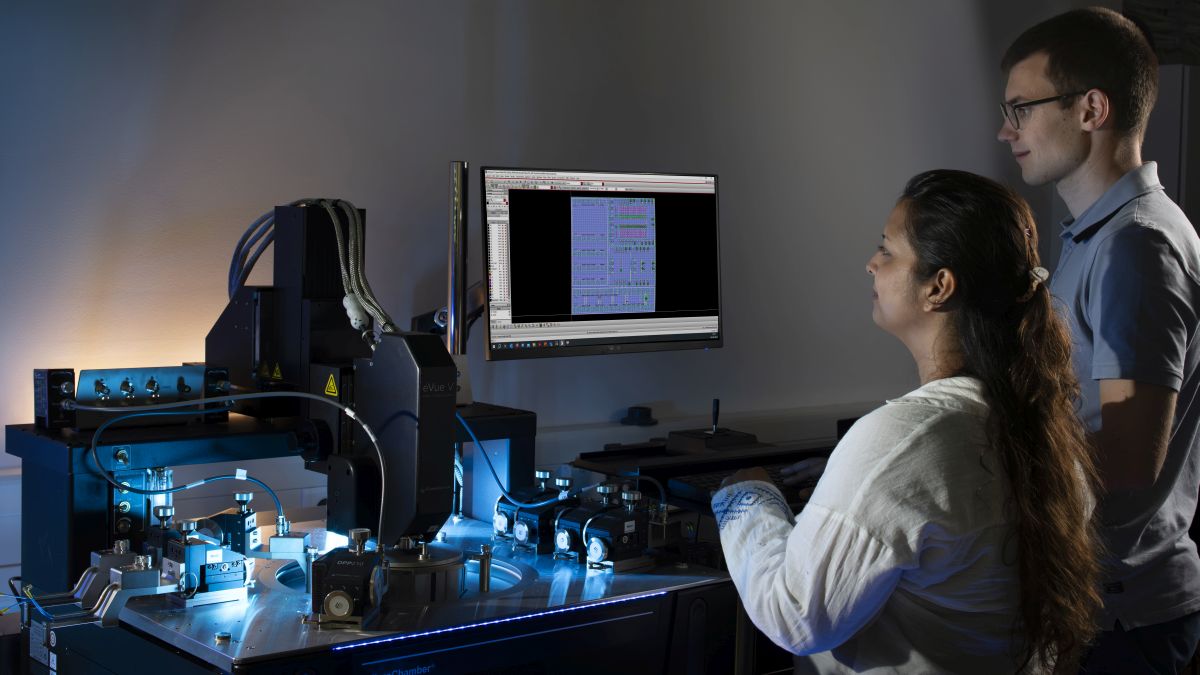

KIT “Callisto” is now being produced at Intel's foundry and the first dies should arrive in Karlsruhe before the end of the year. The team is already looking forward to the electrical verification and characterization.

mhe, July 24, 2024