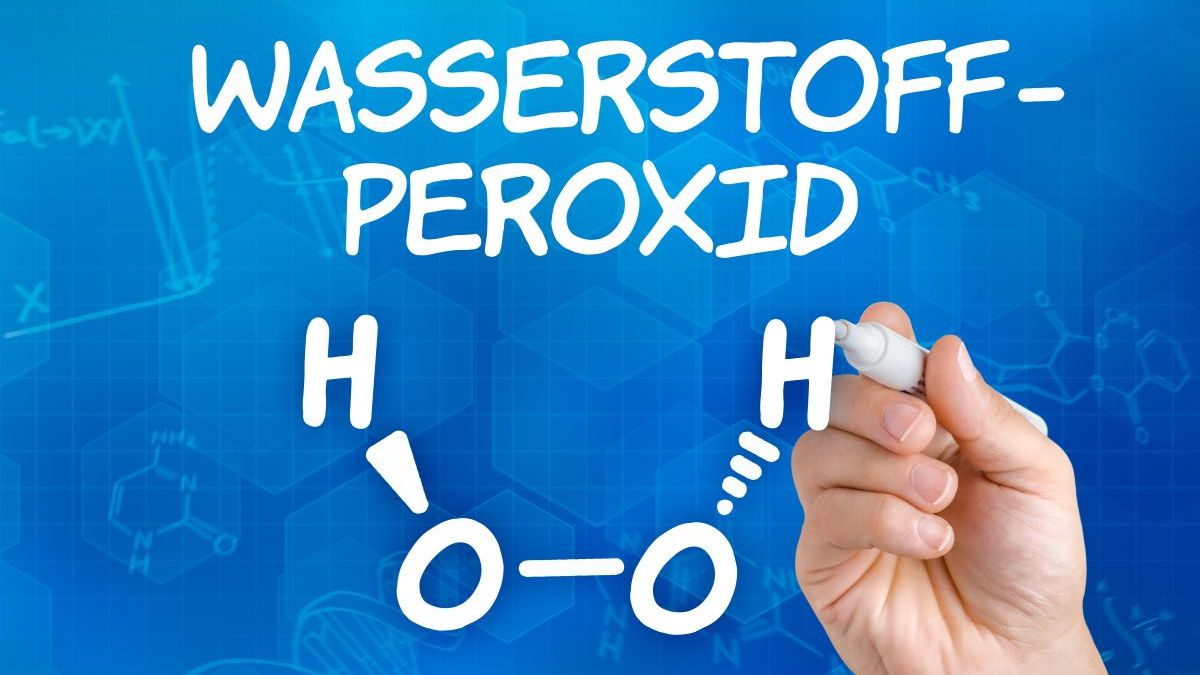

Millions for the Everyday Product Hydrogen Peroxide

Hydrogen peroxide – or H202 – is everywhere. It is used as a bleaching agent for hair or paper, or as a component of disinfectants and sterilization agents in households, industry and medicine. In order to systematically research existing, competing sustainable production methods, the German Research Foundation (DFG) is now funding the HyPerCat research group at the Karlsruhe Institute of Technology (KIT).

Avoiding long transport routes

As a rule, this everyday product is manufactured using chemical synthesis in large, expensive plants. "This means long transport routes to the end customers, which is not particularly sustainable," explains Professor Silke Behrens, from the Institute for Catalysis Research and Technology at KIT and spokesperson for HyPerCat. "With our group, we therefore want to take a closer look at electro- and thermocatalytic direct synthesis." These methods can be used to produce hydrogen peroxide in small units, which is more sustainable.

The research group wants to investigate systematically which of the two methods is better and to what extent the good properties of one method can be combined with those of the other. "This includes how the atoms react with each other, right up to the value chain on an industrial scale," says Behrens. To this end, the HyPerCat project is divided into eight subprojects. Seven of them are located at KIT, one at the Technical University of Berlin. In the long term, the researcher also hopes to gain insights that will enable more complex processes such as ammonia synthesis to be made more sustainable.

The DFG is funding HyPerCat with 3.9 million euros over four years.

iha, 16.07.2024